GEneral engineering & Fabrication in Atherton

- Fully equipped mobile workshop available 24/7 for on-site repairs & diagnostics

- Over 40 years’ experience servicing agriculture, mining & heavy machinery

- Fast turnaround on machining, welding & hydraulic component servicing

Request a call back

Thank you for contacting McLaren Engineering.

We will get back to you as soon as possible.

Please try again later.

Atherton General Engineering & Fabrication

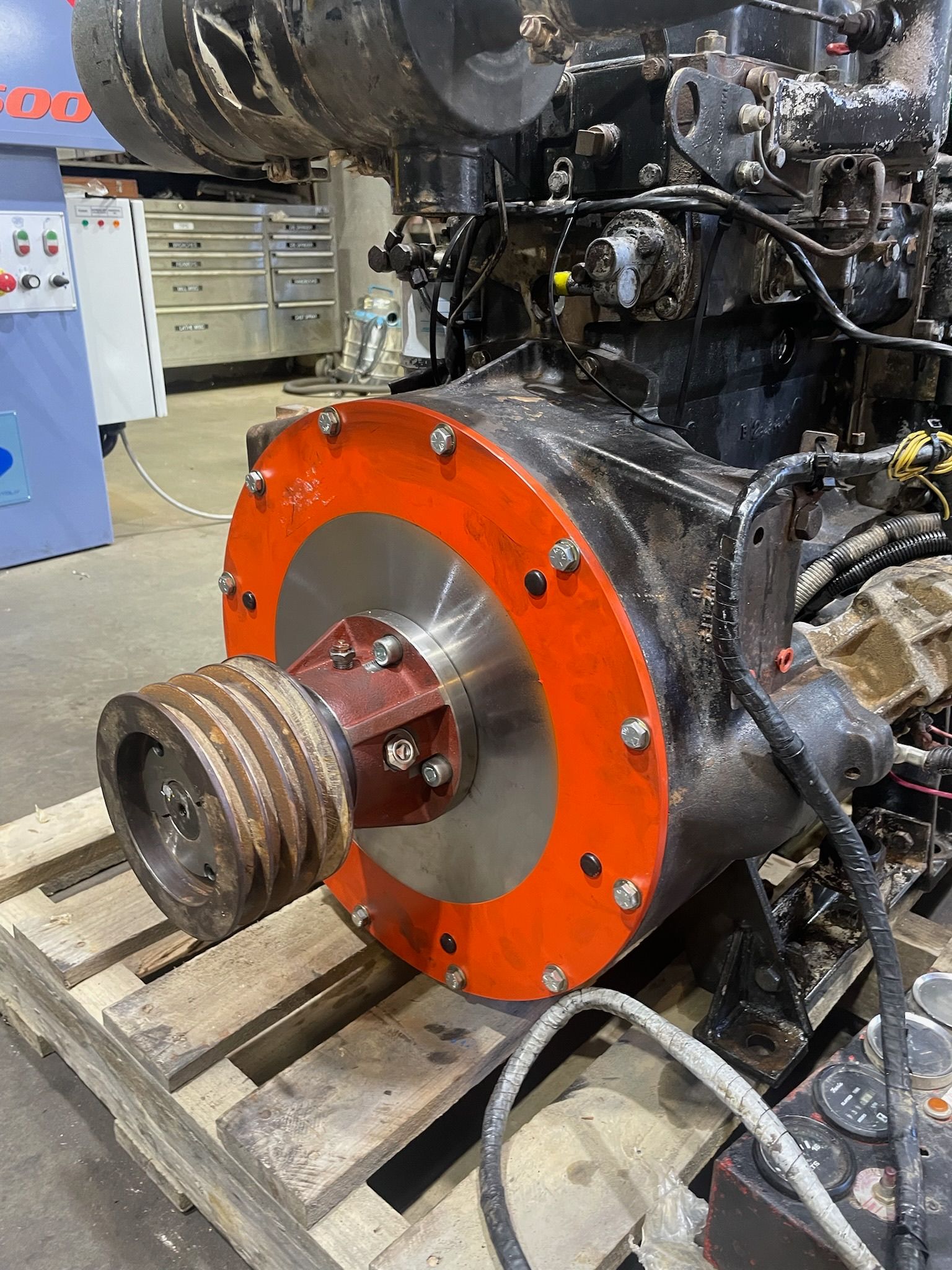

From one-off structural jobs to heavy-duty repairs, McLaren Engineering in Atherton delivers general engineering and fabrication services you can rely on. With over 40 years of experience and a fully equipped mobile setup, we create and repair metal components for farming, transport, mining and construction. Whether you need brackets, custom mounts, structural frames or repairs on-site, we’ve got the tools and the skill to do it.

Our fabrications are built to handle real-world conditions, not just look good on paper. We work with mild steel, stainless, aluminium and more—delivering clean, durable welds every time.

- Welding, cutting & structural repairs

- Custom builds for practical field use

- On-site & workshop fabrication options

Let’s build something that lasts. Call (07) 4095 4633 to discuss your next fabrication or repair job.

Welding & Metalwork That Works

Every job is different—and that’s exactly why we offer flexible engineering and fabrication solutions that can be tailored to your site, timeline and needs. From quick patch-ups to full structural builds, our work is guided by real-world knowledge of how machinery and equipment operate in the field.

We repair, modify and create metal components for trucks, trailers, implements, machinery and infrastructure. If you need a job done fast, we’ll come to you with our mobile welding unit. If it’s a complex fabrication, we’ll take it back to the workshop and deliver the finished product ready to go.

- Fabrication for farming, transport & construction gear

- Strong, neat welds for long-term durability

- Fast turnaround for urgent repairs & reinforcements

No fluff, no fuss—just solid work that holds up under pressure.

Frequently Asked Questions

What industries benefit from general engineering and fabrication?

A wide range of industries rely on fabrication—particularly agriculture, transport, mining, manufacturing and civil construction. Farmers may need custom-built gates or tool attachments, while transport operators might require trailer repairs or load-bearing frames. Mining and construction regularly use custom-fabricated components for plant equipment, conveyors and machine enclosures.

How strong are mobile welds compared to workshop welds?

When done correctly by experienced welders using the right equipment, mobile welds are just as strong and reliable as those done in a controlled workshop environment. The key is proper surface prep, material selection and welding technique. While workshops allow more control over conditions, mobile welding is ideal for structural and urgent repairs where access is a challenge.

What materials can be used in metal fabrication?

Common materials include mild steel, stainless steel, aluminium and cast iron. Each material has different properties that affect strength, corrosion resistance and suitability for welding or cutting. The choice of material depends on what the part is used for, its exposure to the elements and the weight or load it must handle.