Hydraulic Parts in atherton

- Fully equipped mobile workshop available 24/7 for on-site repairs & diagnostics

- Over 40 years’ experience servicing agriculture, mining & heavy machinery

- Fast turnaround on machining, welding & hydraulic component servicing

Request a call back

Thank you for contacting McLaren Engineering.

We will get back to you as soon as possible.

Please try again later.

Atherton Hydraulic Parts & Service

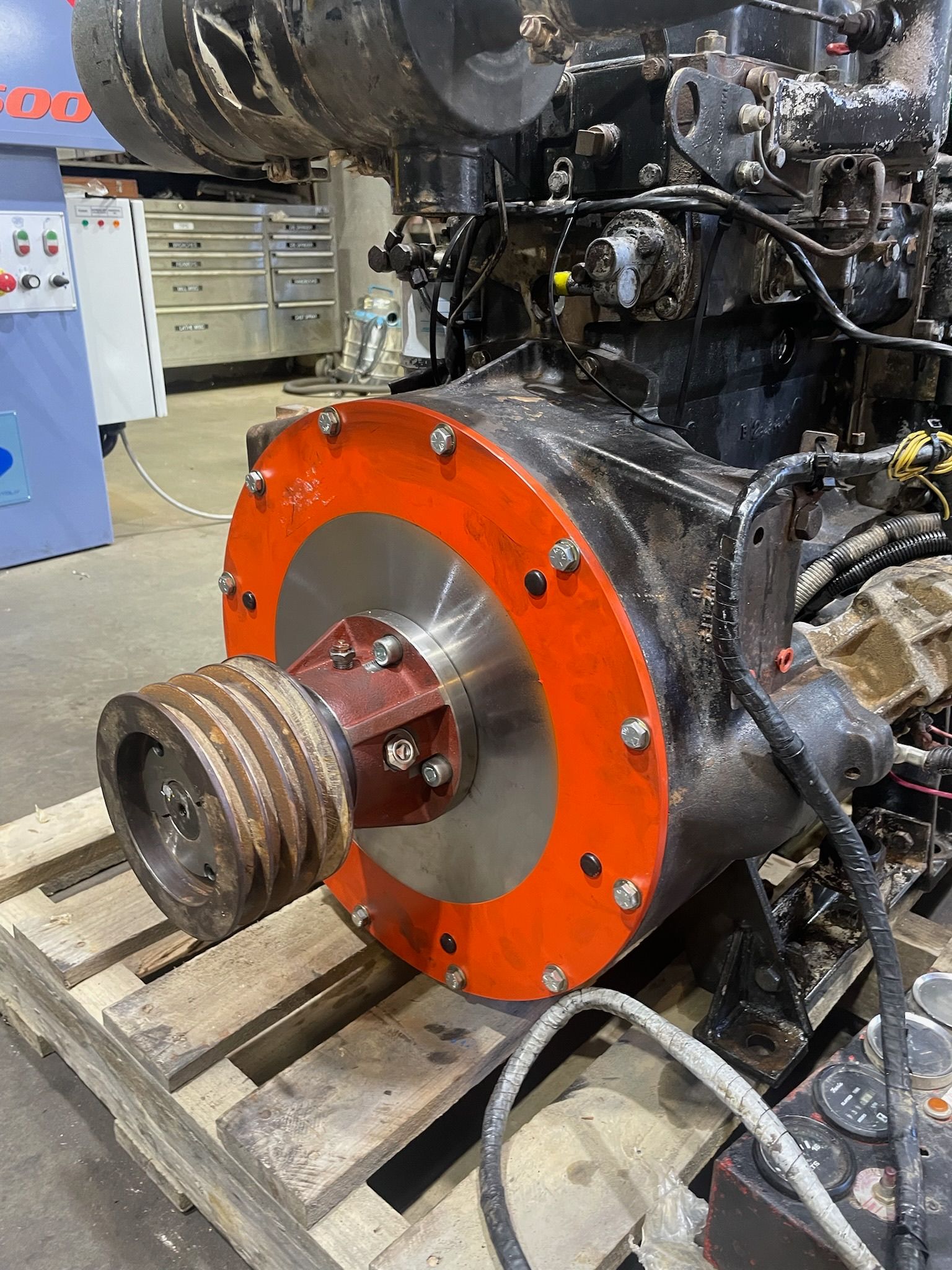

When hydraulic systems fail, everything grinds to a halt. At McLaren Engineering in Atherton, we offer reliable hydraulic parts sales and servicing that helps prevent breakdowns before they happen. Whether you're replacing a worn-out pump, dealing with a leaky valve or need a new cylinder fast, we stock and supply quality parts built for performance. Our team also provides on-site diagnostics and repairs, making it easier to keep systems running without the delay of ordering in or hauling gear off-site.

- Hydraulic pumps, motors, valves & cylinders

- Mobile diagnostics & on-site servicing

- Quality components for long-term reliability

We’re here to make maintenance simple and stress-free. Established in 1985 and offering over 40 years of experience with a fully equipped mobile service, we take the guesswork out of hydraulic repairs and supply.

Call (07) 4095 4633 to book fast, expert help with your hydraulic parts.

Fast, Local Support That Works

Hydraulic systems do the heavy lifting across industries like agriculture, construction and manufacturing—but even the best setups wear down. That’s why we offer a full range of hydraulic services, from supplying new components to carrying out detailed on-site diagnostics and repairs. If something’s not working the way it should, we’ll figure it out and get it fixed without delay.

- Sales, repairs & installation of hydraulic components

- Suits everything from tractors to heavy industrial systems

- Ideal for breakdowns, maintenance or system upgrades

We carry quality hydraulic components including hoses, pumps, valves, motors and cylinders—ready to be fitted as needed. No two systems are the same, so we take the time to find the right fit for your equipment.

Frequently Asked Questions

How do I know if my hydraulic pump is failing?

Common signs of a failing hydraulic pump include unusual noises like whining or knocking, reduced system pressure, sluggish performance or overheating. You might also notice foamy fluid or fluid leaks around the pump. These symptoms often point to problems like internal leakage, fluid contamination or mechanical wear. It’s important to act quickly—ignoring early warning signs can lead to more serious failures elsewhere in the system.

Can hydraulic components be repaired or do they always need replacing?

Many hydraulic components can be repaired, depending on the type and extent of the damage. Cylinders, for example, can often be rebuilt with new seals and rods. Valves may be cleaned and reseated, and pumps can sometimes be repaired if caught early. However, in cases of major wear, cracking or contamination, replacement is usually the better option. A qualified technician will assess the component and help determine the most cost-effective solution.

What are the most common hydraulic components that need replacing?

Hydraulic systems rely on several key components, and over time, certain parts are more prone to wear or failure. These include hoses, seals, pumps, valves and cylinders. Hoses often degrade due to heat, pressure and movement, leading to leaks or bursts. Pumps and motors may fail if contaminated fluid is used or maintenance is delayed. Valves can stick or wear down, especially under heavy use and cylinders may lose pressure due to seal failure. Regular inspection helps identify these issues early.